“Black metal is hot metal.” This was the second time I’d heard the admonition since I’d begun my apprenticeship with the local blacksmith. Shaking my burned digits in an effort to cool them off, or at least alleviate some of the pain, I gingerly reached for the tongs, using them to move what was going to be a colonial-style gun hook further away from the forge. The meaning behind the phrase was pretty simple… too often people assumed that just because a bit of metal near the forge wasn’t burning white hot, it was cool enough to handle. In reality, even a blackened piece of metal was usually more than hot enough to give you a nasty burn.

Plenty of little anecdotes came up in the next year of my apprenticeship, during which I learned all the basics, making everything from ladles, hooks, and railings, to acorns and roses. My goal was the same as most young apprentices: to become a bladesmith. Totally original… and short-sighted. It takes years to become a master blacksmith, and bladesmithing is considerably more specialized. Though I learned plenty, I never became a master bladesmith, instead choosing to enlist in the Marine Corps a year later.

Throughout my five years in the Corps, I kept busy by fixing up blades for my fellow Marines. I’d learned the basics of sharpening from an Eagle Scout back in college, and the rest I learned as I went; tuning pivots, deburring poor machining, removing impressive amounts of rust, and replacing broken parts when needed.This interest also extended to maintaining (and adding to) my personal collection of cutlery. Between my collection and the knives I was fixing for other people, I was able to get a solid grasp on what qualities I wanted in a blade, as well as things I wanted to avoid.

Meanwhile, my experience overall in the military took a turn for the worse. The few good NCOs could not counterbalance the many who were immature and extreme. I didn’t take to being berated daily or singled out for punishments, and especially not to assault. I tried to focus on my reasons for joining and distract myself with learning more about knifemaking. But eventually, the situation caught the notice of higher-ups and civilians, who contacted me to make sure I wasn’t suicidal. I wasn’t, but my passion had long since faded and been replaced by a perpetual whirlwind of stress.

Another mistake. But this burn went a lot deeper than fingers on hot metal. It affected everything—my headspace, my health, my relationships.

Then someone threw me a lifeline. A friend in the Marine Reserves, Matt, had started writing articles for a site called Task & Purpose, and frequently hit me up with questions about knife terminology and how to test different aspects of the knives he was reviewing. After a few months, he bluntly told me that I needed to start writing for them as well. I hemmed and hawed, but eventually he convinced me to submit an article, and what was previously a niche hobby quickly became a new career. My first article was published in August of 2021, and I spent the next year filling my free time with testing, writing, and revising. The outlet from the stress was a godsend and helped financially counter the increased cost of living in California.

After writing for a few months, I was approached by an acquaintance, Don Moore Kramer, who is lead designer at Carnivora Tools. He hit me with one of the strangest and coolest jobs I’ve ever been given: saying the name of an animal, he asked me to design a blade to go with the name. I balked at the opportunity, unable to think of a knife design that wouldn't be a knockoff of someone else's work, or another run-of-the-mill drop-point fixed blade. I knew exactly what features I wanted the handle to have, but for the blade itself, I was experiencing the knife version of writer's block. While I was pondering the question, I went out for a fateful drive—one of my wheels mysteriously detached itself from my car while I was cruising at 40 mph. The aftermath of the accident put any thoughts of knife design out of my mind for the next three months.

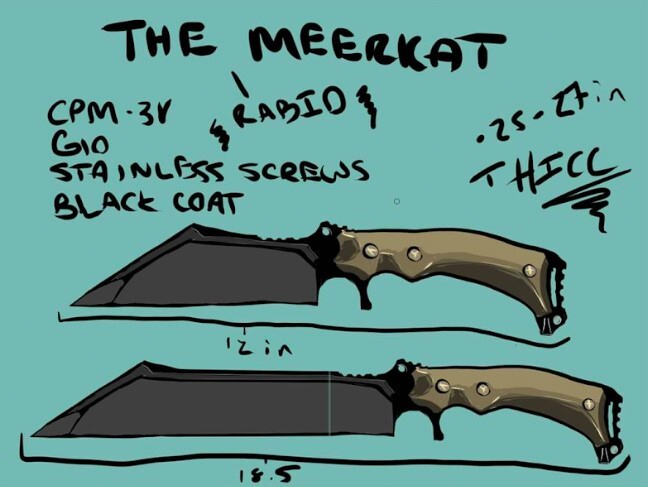

But early last year I had a eureka moment. I'd been working on knife articles for several hours, and had gotten stuck thinking about wharncliffe-style blades. I've always been a fan of the seax in particular, and while it was a very practical, utilitarian design, the tip on some variants could be a little fragile. My writer's block faded, and I immediately started sketching the design, integrating all the other qualities I'd come to prefer in knives. A longer blade-to-handle ratio, maximum edge length in comparison to the overall blade length, and a finger choil/quillon that turned it into a sub-hilt fixed blade. Within minutes, I had a rough draft to send Don, and he began to work his magic.

Now, a year later, the final design work is done, and The Meerkat is ready for prototyping in March. Needless to say, I can't wait. In blacksmithing, in knife design, and in life, I’ve learned to appreciate breakthroughs—and recognize that it’s the mistakes and stumbles that often get us there.

Josiah Johnston is a Marine Corps Veteran of 5 years, originally from the Eastern Panhandle of West Virginia. He's dabbled in blacksmithing, martial arts, and competitive shooting, and is a self-described knife nerd.